Inspect surface texture consistency for perfect matching finishes. Look for gapless, aligned, and sealed joins to prevent water damage. Assess filler and paint quality for durability and seamless integration with surrounding panels. Choose an experienced aluminum panel repair specialist for top-notch results.

“Are you an aluminum panel repair specialist seeking to identify subpar work quickly? This concise guide equips you with crucial tools for evaluating repairs. By inspecting texture consistency, checking joins and seams, and assessing filler and paint quality, you can spot incomplete or poorly executed repairs in seconds. Become the expert that delivers top-tier aluminum panel restoration.”

- Inspect for Lack of Consistency in Texture

- Check Joins and Seams for Improper Fitting

- Evaluate Quality of Used Fillers and Paint

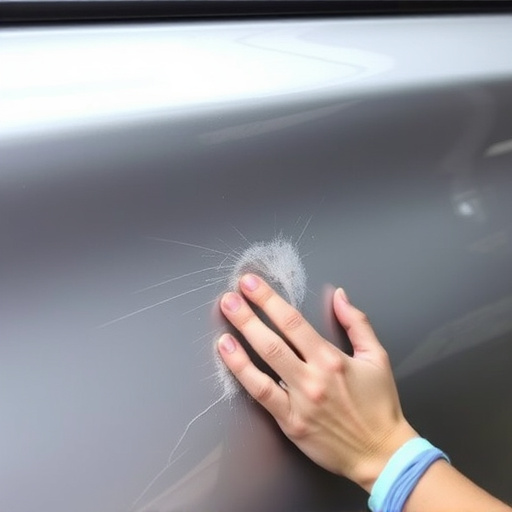

Inspect for Lack of Consistency in Texture

When assessing aluminum panel repair work, one quick visual cue can reveal inconsistencies that point to subpar craftsmanship. Aluminum panels, due to their smooth and sleek surface, should maintain a consistent texture throughout the repair process. A knowledgeable aluminum panel repair specialist will match the original finish perfectly, ensuring no visible differences in the repaired area. If you notice varying textures—some spots feeling smoother or rougher than others—it could indicate that the repair work was not executed by an expert.

This inconsistency might be a result of using different techniques or materials during the repair. For instance, a collision repair center or car body shop might use a less precise method for filling and smoothing dents in an aluminum panel compared to a specialized aluminum panel repair specialist. The former could leave visible evidence of their work, such as faint lines or uneven surfaces, which are usually avoided by professionals who prioritize blending the repaired area seamlessly with the rest of the vehicle’s body.

Check Joins and Seams for Improper Fitting

When assessing aluminum panel repair work, one of the most telling signs of incompleteness or poor craftsmanship is a close inspection of the joins and seams. A qualified aluminum panel repair specialist will ensure that all connections are secure, properly aligned, and sealed to prevent any water intrusion or further damage. If you notice gaps, misalignments, or weak spots in these areas, it’s a strong indicator that the job was not done thoroughly.

Experienced professionals understand the importance of precise fitting when dealing with aluminum panels. Unlike other materials, aluminum requires special care due to its tendency to dent and deform easily. A car dent repair or automotive repair involving aluminum panels must be executed with expertise to avoid visible imperfections or long-term structural issues. By checking for these subtle yet crucial details, you can quickly identify subpar vehicle repair services and ensure the longevity of your vehicle’s exterior.

Evaluate Quality of Used Fillers and Paint

When assessing aluminum panel repair work, one crucial aspect to scrutinize is the quality of filler and paint used. Aluminum fillers come in various forms, from putty to composite materials, each with its strengths and weaknesses. A competent auto painting and aluminum panel repair specialist will choose a filler that matches the original metal’s properties for long-lasting durability.

Moreover, the application of paint over the repaired area is critical. The paint should seamlessly blend with the surrounding panels, ensuring there are no visible gaps or inconsistencies. A car body shop specializing in aluminum repairs should employ high-quality paints designed specifically for automotive applications to withstand various weather conditions and maintain a professional finish.

When assessing aluminum panel repair work, paying close attention to texture consistency, joint fitting, and filler/paint quality are key indicators of a job well done. An experienced aluminum panel repair specialist will ensure these elements align with the original panel’s finish, offering a seamless and durable solution. By quickly identifying any inconsistencies, you can rest assured that the repair meets high standards and will stand the test of time.