Aluminum panel repair specialists play a vital role in maintaining modern architecture and vehicles' structural integrity. They address issues like dents, scratches, and cracks, often caused by weather or accidents. Using techniques such as cold forming, they reshape panels without heating, preserving their original properties. Efficient repairs are crucial for safety and aesthetic appeal, with professionals employing specialized putties, curing compounds, and precision fasteners to replace damaged panels seamlessly. Regular maintenance, including inspections and prompt repairs, along with protective coatings, is essential to prevent further damage, ensuring structures remain strong, safe, and visually appealing over time.

Aluminum panel repair specialists are experts in restoring structural integrity of buildings adorned with these versatile materials. From residential facades to commercial complexes, aluminum panels face constant exposure to weather, pollution, and potential damage. Understanding both the unique properties of aluminum and common issues like denting, cracking, and corrosion is key to effective repairs. This guide delves into the meticulous step-by-step repair process and offers maintenance tips to ensure longevity for these essential structures. Let’s explore how professionals keep our surroundings looking their best with expert aluminum panel repair.

- Understanding Aluminum Panels and Common Damage

- The Step-by-Step Repair Process

- Ensuring Longevity: Maintenance and Prevention Tips

Understanding Aluminum Panels and Common Damage

Aluminum panels, a common material in modern architecture and vehicle construction, offer lightweight durability but are susceptible to specific types of damage. These panels, typically found on buildings, facades, and vehicles, require specialized knowledge for repair. Common issues include dents, scratches, and cracks, often caused by weather conditions, impact from debris or vehicles during accidents, or simple handling mistakes during installation or transportation.

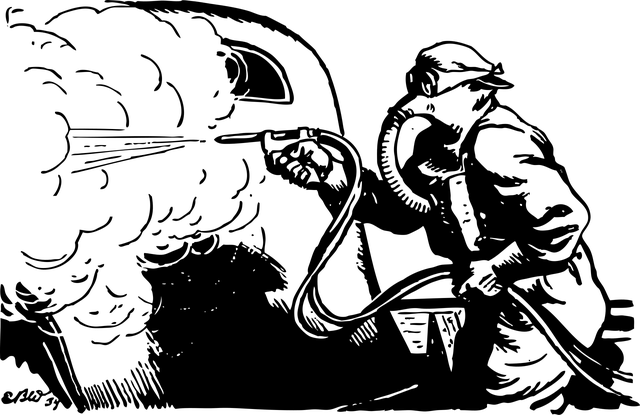

Aluminum panel repair specialists employ various techniques to restore structural integrity. For vehicle collisions or automotive repairs, they might use methods like cold forming, where panels are reshaped without heating, preserving the material’s original properties. This expertise is crucial for ensuring vehicles not only look their best but also maintain safe and sound structural stability after an accident, utilizing efficient and effective aluminum panel repair specialist services.

The Step-by-Step Repair Process

Aluminum panel repair specialists begin by carefully assessing the damage to the aluminum panels, often from accidents or weather events. They then use specialized tools and techniques tailored for aluminum, as it’s a unique metal with specific properties that differ from steel or other common materials.

The process involves several precise steps: first, removing the damaged panel for detailed inspection and repair. Next, they clean and prepare the surrounding area to ensure proper adhesion of new material. Then, they patch and fill any dents or holes using aluminum-specific putties and compounds, allowing these to cure completely. Once ready, a skilled specialist expertly replaces the panel, securing it with precision screws or other fastening methods designed for aluminum’s unique characteristics. Finally, they inspect the work, ensuring structural integrity and a seamless fit, matching the original finish for a discreet repair that blends in with the vehicle’s overall aesthetic.

Ensuring Longevity: Maintenance and Prevention Tips

Aluminum panel repair specialists play a vital role in ensuring the longevity and structural integrity of various structures, from buildings to vehicles. To maximize the lifespan of aluminum panels, regular maintenance is key. Aluminum panel repair specialists recommend periodic inspections to identify any signs of damage or corrosion early on. Promptly addressing issues like dents or scratches through professional auto dent repair services can prevent further deterioration.

Preventive measures such as applying protective coatings and sealing agents also contribute significantly to the preservation of aluminum panels. These measures create a barrier against harsh weather conditions, chemical exposure, and other environmental factors that could compromise structural integrity. By combining timely repairs with proactive maintenance, aluminum panel repair specialists help clients enjoy the benefits of car restoration on a much larger scale, ensuring that structures remain strong, safe, and aesthetically pleasing for years to come.

Aluminum panel repair specialists play a vital role in preserving structural integrity, especially in modern buildings that heavily rely on lightweight yet durable aluminum cladding. By understanding common damage like dents, scratches, and corroded joints, these experts employ precise repair techniques, from meticulous preparation to expert welding. Regular maintenance and prevention strategies, including proper cleaning, coating, and inspection, ensure that repaired panels withstand the test of time, safeguarding both aesthetics and structural soundness. Relying on aluminum panel repair specialists is a smart move for property owners, ensuring their buildings maintain their beauty and strength for years to come.